Exploring the Excellence of China Plastic Molds

Understanding Plastic Molds: The Backbone of Modern Manufacturing

Plastic molds are essential in the production of a vast array of products we encounter daily. From simple household items to intricate automotive components, the role of high-quality molds cannot be overstated. In this article, we will delve deeply into China plastic mold manufacturing, specifically focusing on the capabilities of Hanking Mould, an industry leader renowned for its craftsmanship and innovation in the realm of plastic injection molds.

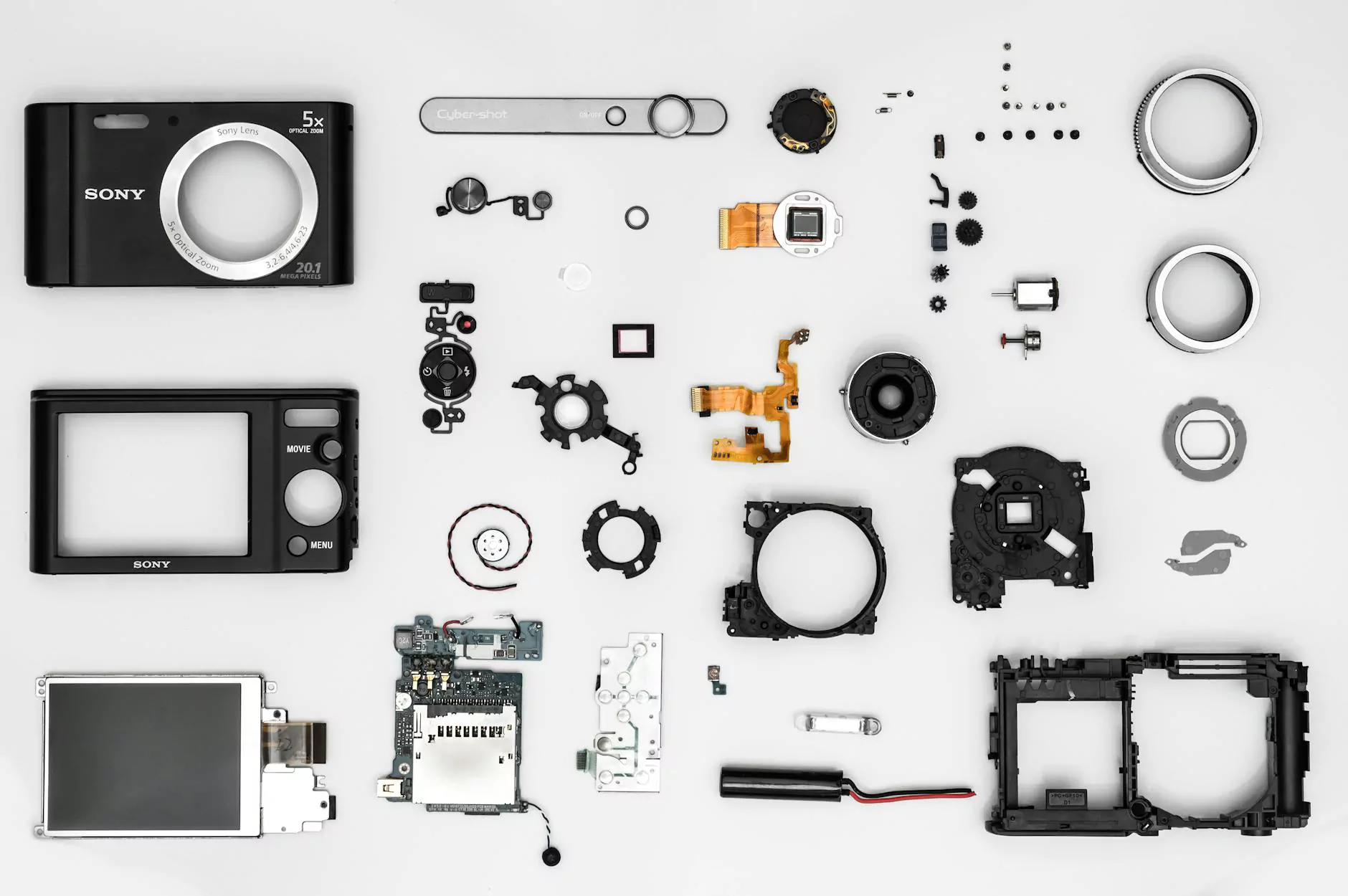

The Process of Plastic Mold Manufacturing

The journey of creating a plastic mold can be complex and requires a combination of art and engineering. Here are the primary stages involved in the process:

- Design: Initial design drafts utilize Computer-Aided Design (CAD) software to create detailed models of the desired product.

- Material Selection: The choice of materials is critical; steel, aluminum, and other composites are commonly employed based on strength, durability, and cost.

- Machining: CNC machining is utilized to carve out specific mold features, ensuring precision and accuracy.

- Assembly: Once machining is complete, the various components are assembled to form the mold.

- Testing: The prototype is tested for functionality and quality through trial runs.

- Production: Upon successful testing, mass production can commence.

The Advantages of Sourcing Molds from China

China has emerged as a powerhouse in the manufacturing sector, particularly in the realm of plastic mold making. Some of the key benefits of choosing China plastic mold manufacturers include:

- Cost Efficiency: Manufacturing in China often translates to lower production costs due to cheaper labor and materials.

- Highly Skilled Workforce: Many manufacturers in China employ skilled engineers and technicians who utilize state-of-the-art technologies.

- Fast Turnaround Times: Advanced manufacturing processes ensure quicker lead times, allowing businesses to meet market demands swiftly.

- Innovative Technologies: Chinese manufacturers are at the forefront of adopting new technologies in mold making, such as 3D printing and advanced CNC machining.

- Robust Supply Chains: Established infrastructure and logistics enable seamless importation and distribution of products worldwide.

Case Study: Hanking Mould’s Commitment to Quality

Hanking Mould exemplifies excellence in the plastic injection mould industry. With decades of experience, they leverage cutting-edge technology and strict quality control processes to deliver superior products. Here are some of the strategies that enable Hanking Mould to thrive:

- Comprehensive Quality Assurance: Each mold undergoes rigorous testing and evaluation to ensure it meets both international standards and client specifications.

- Customer-Centric Approach: Their team works closely with clients, offering tailored solutions and modifications to meet unique project requirements.

- Investment in Technology: Continuous investment in the latest machinery and software allows them to enhance production capabilities and efficiency.

- Commitment to Sustainability: Hanking Mould integrates environmentally friendly practices into their manufacturing processes.

The Future of Plastic Molding in China

The future of the plastic molding industry in China is bright, with several emerging trends that will shape its trajectory:

1. Increased Automation

As the manufacturing landscape evolves, automation will play a significant role in enhancing productivity and minimizing human error. Robotics and AI technologies are rapidly being adopted in production lines across China.

2. Sustainable Practices

The global shift towards sustainability is prompting manufacturers to rethink their processes. Integrating recyclable materials and reducing waste will become priorities for companies striving to maintain competitive advantages.

3. Global Collaboration

Chinese manufacturers are increasingly collaborating with international companies to expand their reach and capabilities, leading to shared knowledge and improved production processes.

4. Customization and Flexibility

As consumer preferences become more personalized, the demand for customized products will rise. Manufacturers who can adapt quickly to these changes will be at the forefront of the market.

Conclusion: Partnering with Hanking Mould for Success

In an ever-competitive landscape, choosing the right partner for your plastic molding needs is crucial. Hanking Mould stands out as a trusted provider in the China plastic mold sector, offering unmatched expertise, quality, and customer service. With their commitment to excellence and innovative practices, businesses can confidently rely on Hanking Mould to bring their visions to life, ensuring not only high-quality products but also long-term partnerships.

Contact Us

Ready to take the next step in your manufacturing journey? Contact Hanking Mould today to discuss how our advanced plastic mold making services can elevate your business and products.