Custom Camshafts Manufacturers: Boosting Diesel Engine Performance

The world of diesel engines is ever-evolving, with many custom camshafts manufacturers leading the way in innovation and performance. These specialized components play a critical role in the overall functioning of diesel engines, directly impacting efficiency, power, and durability. As an industry stakeholder or enthusiast, understanding the significance of custom camshafts and knowing the best manufacturers to trust can make all the difference.

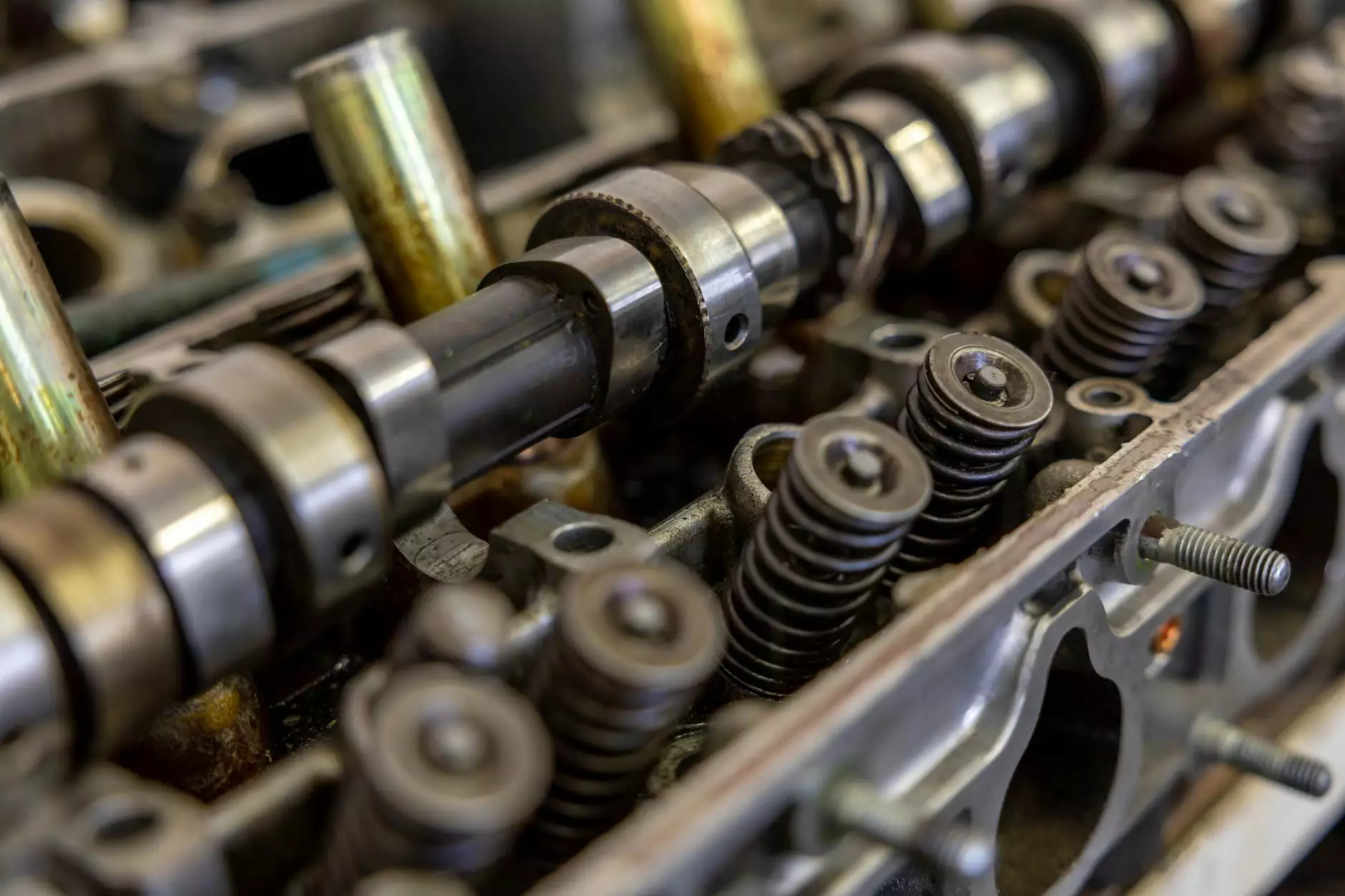

Understanding Camshafts and Their Importance

At its core, a camshaft is an essential component in an engine that controls the timing of valve openings and closings. It is responsible for facilitating the air-fuel mixture intake and exhaust processes. In diesel engines, custom camshafts are particularly crucial due to the unique operational characteristics and design requirements of diesel systems.

What Sets Custom Camshafts Apart?

While standard camshafts may suffice for general applications, custom camshafts are tailored specifically to meet the unique demands of various engine configurations. These bespoke elements are designed based on:

- Engine Type: Different engines have specific requirements based on their design and intended use.

- Performance Goals: Whether for efficiency, power, or torque, custom camshafts are engineered to achieve targeted performance metrics.

- Operational Environment: Conditions such as temperature, altitude, and load can influence camshaft design.

Choosing the Right Custom Camshafts Manufacturers

When in search of top-tier custom camshafts manufacturers, there are several factors to consider to ensure quality, reliability, and performance:

1. Expertise and Experience

Selecting manufacturers with vast experience in custom camshaft production is vital. Established companies likely have more refined design processes and manufacturing techniques. Look for those who have worked with various types of diesel engines and have a portfolio showcasing their expertise.

2. Manufacturing Capability

The capability to produce intricate designs with consistency defines a manufacturer’s quality. Verify if they utilize modern machinery and advanced engineering software for precise design and manufacturing. High-tech equipment can make a significant difference in the performance metrics of the resulting camshafts.

3. Material Selection

The materials used in the production of custom camshafts are crucial for their performance and durability. Top manufacturers often utilize:

- High-Quality Steels: For durability and strength to withstand the rigors of diesel engine operation.

- Alloys: Used to enhance resistance to wear and thermal stability.

- Coatings: Some camshafts may feature specialized coatings to reduce friction and enhance performance.

4. Customization Options

Custom camshafts manufacturers should offer a wide range of customization options tailored to your specific engine needs. This can include alterations to lift, duration, and timing adjustments, among others. Close collaboration with the manufacturer during this phase can yield optimal results.

Innovations in Custom Camshaft Manufacturing

The field of custom camshaft manufacturing is at the forefront of technological advancements. Innovations constantly emerge, enhancing performance and efficiency. Some key innovations include:

Variable Camshaft Timing (VCT)

Many leading manufacturers now incorporate advanced technologies such as Variable Camshaft Timing. This allows for real-time adjustments to be made, optimizing performance characteristics based on driving conditions.

Computer-Aided Design (CAD)

Using CAD technology enables manufacturers to simulate and analyze camshaft performance before physically producing parts. This not only cuts down on production time but allows for better-quality control and optimization of designs.

Advanced Testing Protocols

Innovative testing methods, including dynamometer testing, are now commonplace. These tests provide real-time feedback on camshaft performance, ensuring that only the best products reach the market.

Key Benefits of Custom Camshafts

Investing in custom camshafts manufactured by experts comes with numerous benefits, particularly for diesel engine applications:

1. Enhanced Performance

One of the primary advantages of custom camshafts is the significant boost in overall engine performance. Adjustments to valve timing and lift can lead to increased horsepower and torque, essential for various applications, from racing to heavy-duty work.

2. Improved Fuel Efficiency

By optimizing the air-fuel mixture intake and exhaust flow, custom camshafts can lead to marked improvements in fuel efficiency. This is crucial for businesses relying on diesel engines, as it translates directly into cost savings.

3. Tailored Solutions for Unique Needs

Each engine has specific requirements based on its design and intended use. With custom camshafts, manufacturers can provide tailored solutions that can significantly enhance engine performance and reliability.

4. Increased Longevity

High-quality, custom-designed camshafts can endure the rigorous demands placed on them, leading to decreased wear and a longer lifespan for your engine, which ultimately saves money on replacements and repairs.

Conclusion: Partnering with Top Custom Camshafts Manufacturers

As the diesel engine industry continues to evolve, prioritizing partnerships with reputable custom camshafts manufacturers becomes essential. Companies like client-diesel.com exemplify the commitment to quality, innovation, and customer satisfaction needed in today’s market.

In conclusion, a well-designed camshaft can dramatically alter the performance and efficiency of diesel engines. Manufacturers who invest in advanced technologies, material selection, and collaborative customization can provide significant advantages. In an industry where performance is paramount, choosing the right partner is crucial for success.